Lagoon 450 support

WELCOME TO THE LAGOON 450 OWNER’S SECTION

Dear Lagoon 450’s owners,

At Lagoon, quality and safety are at the heart of the design and manufacture of all our catamarans. We constantly listen to the feedbacks brought by you and through our dealers and service centers.

To accompany the use of your Lagoon 450 throughout its life, you will find in this section useful information, answers to your questions and guidelines to maintain your boat’s seaworthiness and its resale value. In a nutshell, to get the best out of your Lagoon 450.

Be sure our teams are fully dedicated to support you as they have always done.

Best regards,

The Lagoon Team

INFORMATION ABOUT LAGOON FORWARD BULKHEAD

First of all, we want to reassure every owner of a Lagoon 450: we do guarantee you that safety and navigability of your boat are preserved whatever the state of your forward bulkhead be.

This guarantee is based on the results of the study we undertook in March 2021, after we realized that there were several Lagoon 450 affected by a forward bulkhead issue. We actually started analyzing the cases reported to us, with some new calculations based on latest available tools, to understand causes and potential impacts of deformed or broken forward bulkhead.

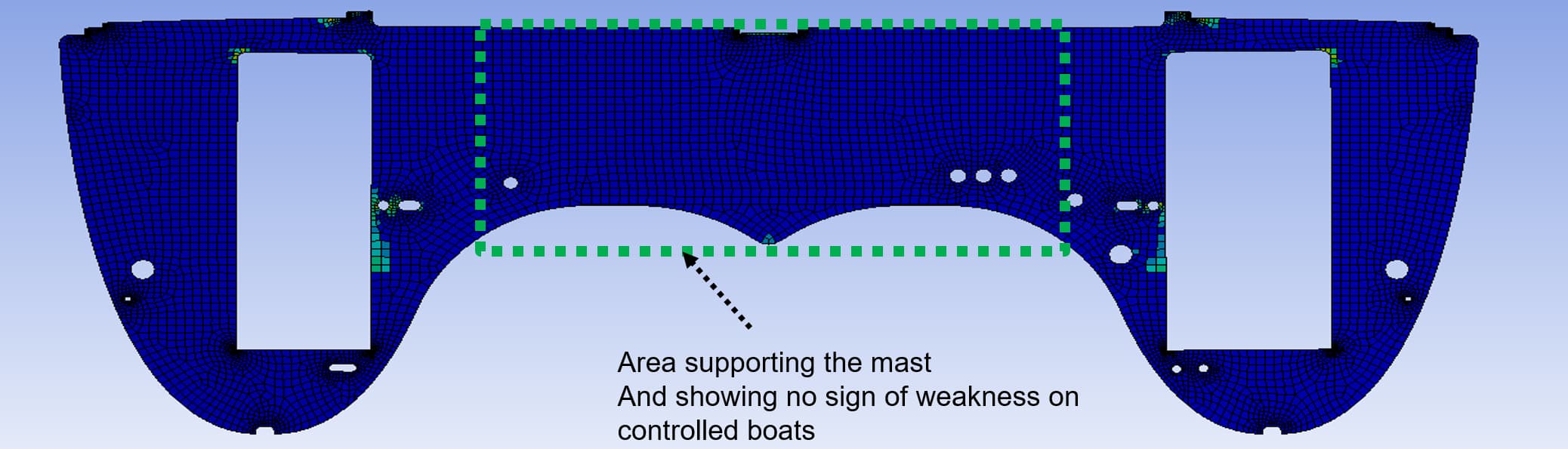

To ensure the reliability of this Finite Element Analysis, we asked VPLP, one of the most renowned international team of naval architects and designers, to review our calculations and results, which they did. They reached the same conclusions as us: there is no safety issue when navigating with a broken or deformed bulkhead. Potential damages on forward bulkhead could not lead to neither dismasting nor any risk for the crew.

How did we come to this conclusion? The forward bulkhead is located in front of the saloon area and is divided into two main areas with different roles:

• The most important one is the central area which withstands 100% of mast compression. This area is stiff and solid. Only this part of the bulkhead has these functions. It cannot be affected by a bulkhead deformation.

• The side parts of the front bulkhead support most of the sea twist effects causing, in a fair number of boats, buckling on its door side. This side part is less rigid to be able to react and guarantee a certain flexibility to the structure of the boat.

A bulkhead is also present in the aft of the boat. This is much less stressed, and it is also rather flexible so it can evolve through navigation time, like many other parts of the boat.

As you may know, at the dock, the mast compression is at least around 9 tons for Lagoon 450. When sailing, this compression increases. So, for the mast to come out of its mast foot would require that the whole boat flex above overall limit of materials: basically, it would mean that the boat breaks apart which has never been the case on cruising catamaran history.

Consequently, we can reassure you that forward bulkhead issue is not a safety issue. It still may become unpleasant if the reinforcement is made late, since bent or buckling bulkhead will only transfer the stress elsewhere.

Flexibility is inherent to the boat’s construction: reinforcing, straightening up or repairing the sides of the bulkhead will still contribute to preserve it and to get the most from your boat, this is why we recommend doing so. Reinforcement, however, will not (and should not), completely remove the flex, as wear naturally comes from boats’ use, just as flexibility: it is and will remain normal to make layout adjustments over time.

HOW TO CHECK, REINFORCE OR FIX THE LAGOON 450 FORWARD BULKHEAD?

Our teams are fully mobilized to support Lagoon 450 owners who wonder about their Lagoon 450 forward bulkhead, who want to reinforce it or who need to fix it.

We developed a 3-step process to support each Lagoon 450 owner on this matter:

STEP 1: CHECK THE FORWARD BULKHEAD STATUS

First, we invite each owner to contact his closest Lagoon Dealer or Lagoon official Service Center to plan a thorough inspection on the forward bulkhead. This operation lasts approximatively 4 hours and its cost will be directly covered by Lagoon.

When you apply for a check, please gather the following information with a Lagoon Dealer or with a Lagoon official Service Center:

1. Hull number

2. Current and past names of the vessel

3. Full name and contact information of the owner

4. Current and past navigational areas of the boat

5. Current and past mooring locations

6. Usage history of the vessel (private, professional or charter)

7. Any sales history of the vessel

8. Any available professional surveys

9. Vessel survey at the purchase date (for secondhand boat only)

10. Any incidents of note for the vessel

11. Any copies of logbooks for the vessel

STEP 2: REINFORCE OR FIX THE FORWARD BULKHEAD

Following this inspection, you will receive an individual diagnostic based on your bulkhead status, boat year of delivery and navigation history. It will include a customized procedure and associated cost estimate, to reinforce or fix the forward bulkhead.

The repair methodology was elaborated with the support of VPLP, our Service Centers, and one independent Marine Surveyor (from the Yacht Designers & Surveyors Association YDSA) who all approved it along with the French official Ministère de la Mer. On these bases, we have started to specify and produce a repair kit, including the dedicated parts needed to be sent to our Dealer or Service Center which will implement our reinforcement or fix procedure. Lagoon will support each Lagoon 450 owner whose boat was subject to normal use*, according to the following guidelines:

- As a commercial gesture, Lagoon will cover the forward bulkhead inspection for every Lagoon 450, when done by its Dealers or Service Centers network (approx. 4 hours of labor);

- For Lagoon 450 under warranty (three years for Lagoon catamarans sold before 2019, and five years for those sold after), Lagoon will take in charge 100% of labor costs and dedicated parts costs in case its owner would wish to reinforce its bulkhead or would need to fix it;

- For all Lagoon 450 out of warranty, Lagoon will provide customized reinforcement / fix methodology and dedicated parts Kits; Regarding Labor costs, Lagoon will deal on a case-by-case basis, depending on the year of the boat delivery an on its navigation history.

- Every reinforcement/fix operated by Lagoon Dealer or Service Center will be certified by Lagoon and will benefit from a 1-year warranty.

*Examples of abnormal use:

- Sailing out of the Owner’s Manual sailing advice:

- Sailing with more sail area than allowed on the Owner’s Manual sailing advice

- Powering against sea and wind for a long time @30° off the true wind

- Sailing in very shallow waters to a point where waves could end up in occasional groundings

- Anchoring in very shallow waters to a point where waves could end up in occasional groundings

- Grounding

- Tightening the rig out of the mast manufacturer specification

- Improper haul out and storage

STEP 3: GET YOUR FIX CERTIFIED

Every repair or reinforcement done by our Dealer or Service Center will be stamped by a one-year warranty certificate (subject to normal use of the boat).

You can also contact our Service Center :

Multitech

info@multitechmarine.net

+1 (954) 522-1114

1601 SW 20th Street Bay

33315 Ft. Lauderdale,

Florida, United States

Caraïbes Gréement

contact@caraibe-marine.fr

+596 (0)5 96 74 80 33

Port de Plaisance, Boulevard Allègre

97290, Le Marin

France

BMS

info@bmsmed.com

+33 (0)4 68 35 02 45

Bât. Quai Ouest - rue Calypso,

66140 Canet en Roussillon,

France

LAGOON ANSWERS YOUR QUESTIONS

1. About the Lagoon 450 bulkhead issue

1.1. Where are bulkheads located in boats and what is their role?

The forward bulkhead is situated in front of the saloon area. It is divided into two mains areas with different roles:

• The most important one is the central area which withstands 100% of mast compression. This area is stiff and solid. Only this part of the bulkhead has these functions. It cannot be affected by a bulkhead deformation.

• The side parts of the front bulkhead support most of the sea twist effects causing, in a fair amount of boat, buckling on its door side. These side parts are less rigid in order to be able to react and guarantee a certain flexibility to the structure of the boat.

A bulkhead is also present in the aft of the boat. This is much less stressed, and it is also rather flexible so it can evolve through navigation time, like many other parts of the boat.

1.2. Why could bulkheads deteriorate?

It is hard to determine the exact cause of this problem, so we are cautious about it as it could result from a combination of different factors such as, for instance:

• Overstressed rig on the long term,

• Long sailing passage against wind and waves too close to the wind under power,

• Grounding,

• Incorrect haul out and storage (Owner’s Manual)

It is also possible that, on some boats, factory construction did not follow the standard methodology, leading to local weakness. Over the years, we have improved our verification procedure in our manufacturing process to deliver consistent quality boats.

There are very few survey reports on second-hand sales which make difficult to narrow down a clear root cause.

1.3. What are the signs and predictors of bulkhead damages or deformation?

Forward bulkhead damages or deformations are not visible at first sight as they are hidden by partition walls and have no impact on navigation. Transversal flexing of the platform is normal and even expected in a catamaran, so it is not a reliable indicator of any potential damage. Squeaking sounds coming for these bulkheads remain the best indicators of such damages.

Although our boats are calculated with plenty of transvers resistance, there is a normal transvers flex: when the mast is stepped on the boat, saloon floor shall flex from 8 to 12mm; with time, this flex can easily increase to achieve around 20mm. With time passing by, elasticity becomes plastic and the bent will remain even if the mast compression is removed.

This explains why we’ve not been informed of such issues over the last ten years.

1.4. What risks do I face when navigating with a broken or deformed bulkhead?

There is no safety issue when navigating with a broken or deformed bulkhead around the hull passages as our studies, checked by VPLP, demonstrated potential damages could not lead to either dismasting or any risk for the crew.

Reinforce, straighten up or repair the sides of the bulkhead will still contribute to preserve the flexibility of the boat and to get the most from your boat. However, flexibility is inherent to the boat’s construction and reinforcement won’t (and should not), completely remove it as wear naturally comes from boats’ use, just as flexibility. This tension evolves over time and preparations of the boat. As a result, it is normal to make layout adjustments.

1.5. Can a broken or deformed bulkhead deteriorate the catamaran?

There is definitely no dismasting or any risk for the crew. This is not a safety issue. It still may become unpleasant if the reinforcement is made late, since bent or buckling bulkhead will only transfer the stress elsewhere.

The quickest way to deal with the problem is to restore normal tension in the boat and prevent other parts from being abnormally stressed. This is why we advise owners to perform the Lagoon protocol, so that they can reinforce their bulkhead or fix any potential damage. Normal tension can be found here

1.6. Is there a risk of dismasting if my forward bulkhead is broken?

There is absolutely no risk of dismasting. When at the dock, the mast compression is at least around 9 tons, when sailing this compression increases. So, for the mast to come out of its mast foot would require that the whole boat flex above overall limit of materials: basically, it would mean that the boat breaks apart which has never been the case on cruising catamaran history.

Bear in mind that on the 1980’s generation of racing trimarans, the flex between the floats and the main hull could exceed 2 meters and never lead to a mast jumping out of its foot: there is always plenty of mast compression left to stand on deck.

1.7. I observe spaces between furniture, my panels are curved, could it be a sign I have a damaged bulkhead?

Not necessarily, as having space between the furniture results from a wear / flex phenomenon, which is completely normal, all boat lifelong. It starts with the first installation of mast and then, increase or decrease with tensions in the boat which is inherent to its preparations and to its proper functioning. It evolves depending on the setting of the rigging and shrouds tension.

1.8. Why is the starboard side often more deformed than the portside in case of a damaged bulkhead?

The forward bulkhead is not symmetrical, which explains the difference between the 2 sides as the tension dispatched differs on them. This does not entail any safety issue.

1.9. If not broken or deformed, should the forward bulkhead be consolidated?

There is no safety issue, so there is no need for an immediate action. However, we recommend to proceed to a reinforcement. Reinforcing the forward bulkhead can be part of a future annual maintenance of the boat at your Lagoon dealership and is recommended by Lagoon. To check what is part of regular maintenance of a Lagoon, please see here.

1.10. If one side of the forward bulkhead is broken, do I have to strengthen the others side?

If only one side of the bulkhead is affected, we recommend consolidating the other side.

1.11. I have a Lagoon 450 under building process. Do I risk any bulkhead issue?

The way we build our boat is always evolving with time, specifically during such a long production time (more than a decade!) as we keep improving our boats to keep them aligned with the best quality standards of their time.

Consequently, on the recent boats, solid wood reinforcement had been added on both sides of the forward bulkhead, then connected together with plywood finish panels on each side of the reinforced bulkhead. This created a stiff beam that will withstand the load and prevent the bulkhead from bending. As of today, no bulkhead deformation issue on those reinforced boats was reported to us.

May the bulkhead issue concern other Lagoon catamarans than the Lagoon 450?

We are not aware of any bulkhead issues on other Lagoon models but we constantly review vessels for potential issues.

In order to reassure owners, we conducted a full inspection of current Lagoon models (40, 42, 46, 50, 52, 55, SIXTY 5, SEVENTY 7) together with VPLP Yacht Design.

Lagoon constantly monitors their boats for any structural or safety issue.

Over 6000 Lagoon catamarans currently navigate around the world, most of them intensively, thanks to Lagoon expertise, in total safety.

It is important to remember that wear naturally comes from boats’ use, just as flexibility. It evolves depending on the setting of the rigging and shrouds tension. This tension evolves over time and preparations of the boat. As a result, it is normal to make layout adjustments.

2. About Lagoon's bulkhead issue management

2.1. For how long have you been aware of the forward bulkhead issue?

Until 2020, only a few isolated cases were reported to us and involved boats with intense charter use.

Since then, we started to be notified by individual owners that they encountered this phenomenon of bulkhead deformation.

Lagoon is constantly monitoring its products throughout their lifetime, and thanks to very experienced users, with whom we constantly collaborate, Lagoon keeps improving its models during their production time, benefiting from the latest and best know-how.

As a reminder, over 1 000 Lagoon 450 have been produced since 2011 and navigation issue linked to bulkhead deformation has never been reported to us.

2.2. How many boats are currently concerned by the bulkhead issue?

Up to now, in August 2021, we have been contacted by 155 Lagoon 450 owners, asking for a check or for a fix methodology.

Amongst cases reported to us, when a damage was found, in 80% of cases, an average of 30 labor hours of repair were required.

2.3. How many boats have registered for inspection/fix protocol and how many have got through it?

The protocol was developed in May 21, after some proper investigation, as the first damaged bulkhead reports have really come to us recently.

Up to now, in August 21, we are in touch with 155 owners. We provide them an individual support, at each step of the process:

• 15 owners have an appointment scheduled to check their bulkhead.

• 32 owners are currently in the repair process;

• 18 boats got their bulkheads entirely repaired (when they were broken) or reinforced (when their owners asked for it).

• We are collecting the data for the remaining ones

Our teams are fully mobilized to bring you the best solution. Unfortunately, the Covid pandemic drastically slows down our technical support teams’ travels and is making the supply and the shipping of the parts difficult, especially to the USA. We are sorry for the delay.

2.4. What is the status of the Lagoon 450 bulkheads checks?

So far, 97 boats have already been checked. What is important to know is that when a damage was found, in 80% of cases, an average of 30 labor hours of repair was required.

2.5. Why are bulkheads different on models before 2012 from the ones built after?

The reason why we changed our bulkheads model after 2012 is that, after hull 36, the factory asked to add stiffeners under the door access to forward cabin (or starboard head in 3 cabins version) to help the doors close easier.

The way we build our boat is always evolving with time, specifically during such a long production time (more than a decade!). We keep improving our boats all their production long, to offer boats always aligned with the best quality standards of their time.

2.6. Don’t the several reinforcements made on Lagoon 450 bulkheads in 2012, and later, acknowledge an issue with the original conception?

No. This reinforcement was not linked to observation of bulkhead side buckling as this issue is very recent for us. The way we build our boat is always evolving with time, specifically during such a long production time (more than a decade!). We keep improving our boats throughout their production, to offer boats always aligned with the best quality standards of their time.

It is hard to determine the exact cause of this phenomenon, so we are cautious about it as it could results from a combination of different factors such as, for instance:

• Overstressed rig on the long term,

• Long sailing passage against wind and waves too close to the wind,

• Grounding,

• Incorrect haul out and storage.

It is also possible that, on some boats, factory construction did not follow the standard methodology, leading to local weakness. Over the years, we have improved our verification procedure in our manufacturing process to deliver consistent quality boats

There are very few survey reports on second-hand sales, which makes it difficult to narrow down a clear root cause.

Lagoon will organise a Technical, Usage & Quality feedback from users on Year 5 and Year 8 of all of its models starting Fall 2021, through its dealers’ network.

2.7. What has been done so far to check the Lagoon 450 situation?

When we realized, in March 2021, that there were several other Lagoon 450 affected, we immediately started analyzing the cases which were reported to us, with some new calculations based on latest available tools.

The Finite Element Analysis, checked by VPLP naval architects, confirms the Lagoon 450 respects the safety coefficient standards: the scantling is sufficient under normal use of the boat. These conclusions also highlighted that potential damages could not lead to either dismasting or any risk for the crew.

Then, we prepared a repair methodology with the support of VPLP, our Service Center, and one independent Marine Surveyor (from the Yacht Designers & Surveyors Association YDSA) who all approved it along with the French official Ministère de la Mer. On this basis, we have started to specify and produce repair kits, including the dedicated parts needed.

Documents available:

VPLP MARVIN- Lagoon 450

Since then, we informed our Dealers network and Service Center about this methodology and set up a response team focusing on this bulkhead issue, to better manage Lagoon 450’s owners enquiries on that matter. However, the Covid pandemic is drastically slowing down our technical support teams’ travels and is making the supply and the shipping of the parts difficult, especially to the USA.

3. About Lagoon's technical support for Lagoon 450 owners

3.1. Can I check the forward bulkhead on my own?

We strongly recommend processing this check through a Lagoon Dealer / Service Center to ensure a qualified diagnostic. It makes all the more sense that the check process (an average of 4 hours) is only covered at Lagoon’s cost when done in our network.

3.2. Where and when can Lagoon inspect my bulkhead?

Your repair will be inspected by a Lagoon Dealer / Service Center. Please contact them to schedule an appointment. For accessing the full list worldwide and their contact details, please click here.

Just bear in mind that, how sorry we are about it, the Covid pandemic is slowing down our technical support teams’ travels and is making the supply and the shipping of the parts difficult, especially to the USA and for those who are far from one of our 85 Dealers and Service Center.

3.3. If the bulkhead is deformed or broken, can I repair it by myself?

No. We strongly recommend you get this work performed by a Lagoon Dealer / Service Center for 2 reasons:

• You will benefit from a fix methodology checked by VPLP.

• The fix will be certified by Lagoon with a 1-year warranty

3.4. Does Lagoon provide manual guidelines to fix the issue?

Lagoon is providing a dedicated methodology for each boat impacted. To do so, the Lagoon response team needs to get as much information as possible.

The complete list of information required is:

1. Hull Number

2. Current and past names of the vessel

3. Full name and contact information of the Owner.

4. Current and past navigational areas of the boat.

5. Current and past mooring locations

6. Usage history of the vessel (private, professional or charter)

7. Any sales history of the vessel.

8. Any available professional surveys.

9. Vessel survey at the purchase date (for secondhand boat)

10. Any incidents of note for the vessel.

11. Any copies of logbooks for the vessel

3.5. Could I call a Lagoon engineer to receive guidance?

We would not be able to ensure an individual regular follow-up of each personal case: the main point of contact is your closest Lagoon Dealer / Service Center which is directly connected to us and has access to Lagoon technical data, should they look for more information.

This is the best way for us to provide answers and support to 450 owners, whoever and wherever they are, which is our goal, having in mind that the Covid pandemic drastically slows down the circulation of our technical support teams and tailored parts sending, especially to the USA, what we are sorry about.

3.6. How do I know if my catamaran is eligible for the Lagoon support protocol and what is Lagoon process to fix bulkhead issue?

Each boat subject to normal use, whatever be its age, will be supported by Lagoon. The level of support will depend on the boat delivery date and on its own history. It will also be based on your own bulkhead diagnosis. On these bases, our Dealer or Service Center and our technical teams will develop a dedicated methodology for each case, which explains why we cannot present one standard process.

Information to be provided to our teams will be the following:

1. Hull Number

2. Current and past names of the vessel

3. Full name and contact information of the Owner.

4. Current and past navigational areas of the boat.

5. Current and past mooring locations

6. Usage history of the vessel (private, professional or charter)

7. Any sales history of the vessel.

8. Any available professional surveys.

9. Vessel survey at the purchase date (for secondhand boat)

10. Any incidents of note for the vessel.

11. Any copies of logbooks for the vessel

3.7. What do you mean by a normal use of Lagoon 450?

Examples of abnormal use of a Lagoon 450 (all examples are common sense and most can be found in the Owner’s Manual):

• Sailing out of the Owner’s Manual sailing advice:

◦ Sailing with more sail area than allowed on the Owner’s Manual sailing advice

◦ Powering against sea and wind for a long time @30° off the true wind

◦ Sailing in very shallow waters to a point where waves could end up in occasional groundings

◦ Anchoring in very shallow waters to a point where waves could end up in occasional groundings

◦ Grounding

◦ Tightening the rig out of the mast manufacturer specification. Check the Dock Tune

◦ Improper haul out and storage (Owner’s Manual)

3.8. Where can I get my broken bulkhead repaired?

You should get this work performed by a Lagoon Dealer / Service Center for 2 reasons:

• You will benefit from a fix methodology checked by VPLP.

• The fix will be certified by Lagoon with a 1-year warranty

Click here to access to the list of our points of services worldwide and their contact details.

3.9. How long will the bulkhead reinforcement take?

It is difficult to give a reliable timing evaluation: we are fully dedicated to support every Lagoon 450’s owner who would apply for reinforcement, bearing in mind that the Coid pandemic is slowing down our technical support teams’ travels and is making the supply and the shipping of the parts difficult, especially to the USA. The operation by itself, in most of the cases, can be performed within an average of 30 hours.

3.10. For how long will Lagoon provide this support? Do we have a deadline to check and repair our bulkhead?

The support will be available as long as needed, because Lagoon is deeply committed to support Lagoon 450 owners and to reassure them about their boat seaworthiness and their resale value.

Just bear in mind that, as sorry as we are about it, the Covid pandemic slows down the circulation of our experts and delays bulkhead diagnostic, reinforcement and fixing operations, especially for those who are far from our network of 85 Dealers and Service Center.

3.11. What are Lagoon recommendations regarding the use and care of catamarans?

There are 10 golden rules to get the best out of your catamaran throughout the years:

1. Detailed inspection of hull(s) underwater area including antifouling condition

A periodical haul out and bottom paint of your boat will keep her original performances and avoid any adhesion of marine vegetation.

The type of the water where you boat sails determines how to choose the antifouling paint as well as how often to carry out these careenings. Do not hesitate to contact your nearest Lagoon dealer for advice.

2. Regularly inspect deck surface and hardware parts (see Owner’s Manual)

3. Periodically, inspect standing rigging and tighten adjustments

4. Regularly run rigging inspection

5. Periodically, inspect, clean and grease of hardware parts

6. Periodically, complete steering system inspection

7. Periodically, control electrical circuits and their maintenance, electronic circuits and their components as well as engine(s) and generator maintenance

8. Periodically, control interior equipment and wooden layout status

9. Always inspect the boat when you encounter difficult or exceptional sea conditions or following a sea event to prevent possible damage, which could progressively worsen over time.

10. Before any purchase or resale of boats and before transaction, it is highly recommended to carry out a preliminary survey performed per a certified surveyor approved by the local authorities of the country.

For more information, please, check the Owner’s Manual here.

3.12. How will Lagoon certify that the fixing implemented by the Dealer or Service Center is completed in accordance with their instructions?

Lagoon is providing the full methodologies to its Dealers and Service Center to check the repairs and to perform it, if needed. Our response team works in close relation with them and follows each case on an individual basis.

In addition, the fixing will benefit from a 1-year warranty from Lagoon.

4. About Lagoon's expenses support for Lagoon 450 owners

4.1. How long is my Lagoon 450 covered by the structure warranty?

3 years for boats delivered before 2019; 5 years for those delivered from 2019.

4.2. How much do inspection expenses represent and does Lagoon cover them?

Inspection expenses represents an average of 4 hours and are covered by Lagoon for every Lagoon 450.

4.3. What could be covered by the brand after the warranty?

Lagoon will support each Lagoon 450 owner whose boat was subject to normal use* according to the following guidelines:

• As a commercial gesture, Lagoon will cover forward bulkhead inspection for every Lagoon 450, when done by its Dealers or Service Center network (an average of 4 hours of labor);

• For all Lagoon 450 out of warranty, Lagoon will provide customized reinforcement / fix methodology and dedicated parts Kits; Regarding Labor costs, Lagoon will deal on a case-by-case basis, depending on the year of the boat delivery an on its navigation history.

• Every reinforcement/fix operated by Lagoon Dealer or Service Center will be certified by Lagoon and will benefit from a 1-year warranty.

*Examples of abnormal use of a Lagoon 450 (all examples are common sense and most can be found in the Owner’s Manual):

• Sailing out of the Owner’s Manual sailing advice:

◦ Sailing with more sail area than allowed on the Owner’s Manual sailing advice

◦ Powering against sea and wind for a long time @30° off the true wind

◦ Sailing in very shallow waters to a point where waves could end up in occasional groundings

◦ Anchoring in very shallow waters to a point where waves could end up in occasional groundings

◦ Grounding

◦ Tightening the rig out of the mast manufacturer specification. Check the Dock Tune

◦ Improper haul out and storage (Owner’s Manual)

4.4. Are you able to provide a cost estimation for the different repair options: veiled, bent, broken bulkhead and impacted boat?

We found out very different cases, from intact bulkhead to lightly veiled, bent or a few broken.

Needed labor hours, depending on cases, can go from 20 to 200 hours but, up to now, amongst cases reported to us, when a damage was found, in 80% of cases, an average of 30 labor hours of repair were required.

4.5. Will Lagoon take in charge the bulkhead reinforcement?

Lagoon will support each Lagoon 450 owner whose boat was subject to normal use* according to the following guidelines:

• For Lagoon 450 under warranty (three years for Lagoon catamarans sold before 2019, and five years for those sold after), Lagoon will take in charge 100% of labor costs and dedicated parts costs in case its owner would wish to reinforce its bulkhead;

• For all Lagoon 450 out of warranty, Lagoon will provide customized reinforcement methodology and dedicated parts Kits; Regarding Labor costs, Lagoon will deal on a case-by-case basis, depending on the year of the boat delivery an on its navigation history.

• Every reinforcement operated by Lagoon Dealer or Service Center will be certified by Lagoon and will benefit from a 1-year warranty.

*Examples of abnormal use of a Lagoon 450 (all examples are common sense and most can be found in the Owner’s Manual):

• Sailing out of the Owner’s Manual sailing advice:

◦ Sailing with more sail area than allowed on the Owner’s Manual sailing advice

◦ Powering against sea and wind for a long time @30° off the true wind

◦ Sailing in very shallow waters to a point where waves could end up in occasional groundings

◦ Anchoring in very shallow waters to a point where waves could end up in occasional groundings

◦ Grounding

◦ Tightening the rig out of the mast manufacturer specification. Check the Dock Tune

◦ Improper haul out and storage (Owner’s Manual)

4.6. Will Lagoon take in charge the damaged or broken bulkhead fixing costs?

Lagoon will support each Lagoon 450 owner whose boat was subject to normal use* according to the following guidelines:

• For Lagoon 450 under warranty (three years for Lagoon catamarans sold before 2019, and five years for those sold after), Lagoon will take in charge 100% of labor costs and dedicated parts costs in case its owner would need to fix its bulkhead;

• For all Lagoon 450 out of warranty, Lagoon will provide customized fix methodology and dedicated parts kits; Regarding Labor costs, Lagoon will deal on a case-by-case basis, depending on the year of the boat delivery an on its navigation history.

• Every fix operated by Lagoon Dealer or Service Center will be certified by Lagoon and will benefit from a 1-year warranty.

*Examples of abnormal use of a Lagoon 450 (all examples are common sense and most can be found in the Owner’s Manual):

• Sailing out of the Owner’s Manual sailing advice:

◦ Sailing with more sail area than allowed on the Owner’s Manual sailing advice

◦ Powering against sea and wind for a long time @30° off the true wind

◦ Sailing in very shallow waters to a point where waves could end up in occasional groundings

◦ Anchoring in very shallow waters to a point where waves could end up in occasional groundings

◦ Grounding

◦ Tightening the rig out of the mast manufacturer specification. Check the Dock Tune

◦ Improper haul out and storage (Owner’s Manual)

4.7. Will Lagoon pay needed parts for my repairs?

For every Lagoon 450 subject to normal use, Lagoon will provide customized reinforcement / fix methodology and dedicated parts kit.

4.8. Under which concrete conditions will Lagoon financially support Lagoon 450 bulkhead reinforcement or repair?

• Expenses taken in charge by Lagoon will be directly managed with the Dealer / Service Center

• Expenses taken in charge by the owner will be paid directly by himself to the Dealer/Service Center

As a reference for exclusion from Lagoon financial support, here are Terms of Lagoon Guarantee, as defined in our General Terms and Conditions of Sale:

The Warranties shall not apply to the following events, deteriorations and structural damages as well as their potential consequences:

• Parts that rapidly deteriorate due to wear and tear, including but not limited to sails, paints, running rigging, batteries, external decorations, cushions, antifouling, anodes, filters, etc.

• Costs of transporting, towing, hauling out, storing, dry-docking or skippering the boat. Customs fees and shipping costs of any defective part and/or equipment as well as any additional costs due to the impossibility of using the boat and/or the equipment, which are to be borne exclusively by the purchaser-user.

• Paint or gel-coat fissures, cracks, fading or discoloration.

• Any repairs or alterations made to the boat by any person or entity not approved to do so in writing by the builder prior to the repairs or alterations.

• Damage resulting from:

◦ ◦ Non-observance of maintenance recommendations as described in the manual issued with the boat, or non-compliance with generally accepted good practices of boat maintenance,

◦ ◦ Improper use, especially negligent, reckless, abusive or abnormal use,

◦ ◦ Sanding of gel-coat,

◦ ◦ Corrosion or slow deterioration,

◦ ◦ Inappropriate handling, storage or transportation conditions,

◦ ◦ Participation in competitions,

◦ ◦ Installation of parts from a different origin and/or modification, alteration of original parts

◦ ◦ Negligence with respect to taking necessary precautionary measures,

◦ ◦ Accident or disaster such as explosion, fire, flood, storm, lightning, transportation, riot, theft, shock, collision, stranding/beaching or any other force majeure event.

4.9. Will my reparation benefit from a warranty? If yes, for how long?

Yes, you will benefit from a 1-year warranty from Lagoon when done by our dealers or Service Center network.

INFORMATION ABOUT LAGOON 450 MAST COMPRESSION POST

WHAT TO KNOW ABOUT LAGOON 450 MAST COMPRESSION POST

More than 1,000 Lagoon 450 have been sailing in full navigability and safety all over the world, for over 10 years for some of them.

At the end of December 2022, for the first time, two cases of damaged mast compression posts were reported and, fortunately, did not lead to any consequence. With the support of our local dealers, repairs were carried out and the boats are running again in full safety.

We carried out in-depth analyses in relation to these cases and ran a series of inspections of this part on a representative number of Lagoon 450 and the vast majority of the inspected boats were fine.

Therefore, because safety is of utmost priority to Lagoon, we recommend to those of you, whose yearly maintenance is planned beyond 6 months, to get their mast compression post checked by their Dealers and Service Centers network, as a precautionary principle.

If your mast compression post is fine, it will just need to be checked once a year as a new routine, within annual maintenance. In case of signs of aging (corrosion, cracks), please contact your Lagoon dealer / Service Center, who will plan its replacement with you, according to a specific and proofed methodology.

MAST COMPRESSION POST: LAGOON ANSWERS YOUR QUESTIONS

1. About the Lagoon 450 mast compression post

1.1. Where is the mast compression post and what is it role?

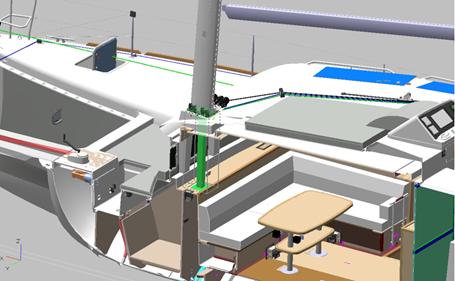

• The mast compression post is a structural element of a boat: it is a beam or a post (tubular or square) of metal construction, placed vertically and used as a support structure for the decks and masts to transmit forces.

• On the Lagoon, 450, the mast compression post, which ensures the connection between the mast, the deck, the hull, and the bulkhead is located at the front of the square.

1.2. What is the "normal" life span of a mast compression post?

• There is no standard to speak of on this point. The life of a steel mast compression post can be very long, depending on the use, the history of the boat and the interventions that have been carried out at the level of the passage of the cables coming from the mast, in the mast compression post.

• Nevertheless, as complete maintenance of rigging is recommended every 10 years, replacing a mast compression post can be considered at that time.

1.3. What are the risks associated with this mast compression post corrosion?

- It depends on the level of corrosion, but as it has a major support role for the mast, if it shows signs of corrosion or damage, it is important to replace it quickly to avoid the failure of the mast compression post head.

- At an early stage, in the event of corrosion or apparent crack located on the upper area of the mast compression post, it is recommended to sail with the engine to limit the compression on the mast and to replace it as soon as possible.

- If the mast compression post breaches, you must stop sailing and arrange for the replacement of the mast compression post immediately.

1.4. What are the risks associated with this mast compression post corrosion?

- It depends on the level of corrosion, but as it has a major support role for the mast, if it shows signs of corrosion or damage, it is important to replace it quickly to avoid the failure of the mast compression post head.

- At an early stage, in the event of corrosion or apparent crack located on the upper area of the mast compression post, it is recommended to sail with the engine to limit the compression on the mast and to replace it as soon as possible.

- If the mast compression post breaches, you must stop sailing and arrange for the replacement of the mast compression post immediately.

1.5. Can I still sail with a damaged mast compression post?

- It all depends on the level of damage to the mast compression post, as the mast compression post has an important supporting role.

- In any case, the boat should not be sailed under sail and the mast compression post should be replaced on return to port:

- At an early or intermediate stage, if the upper mast compression post shows the beginning of a crack or traces of corrosion, it is recommended to sail under engine to limit the compression at the mast and to contact your dealer or your Lagoon Service Center. The dealer will inspect the mast compression post, make a diagnosis, contact the Lagoon boatyard to check the availability of replacement parts and will organize a replacement as soon as possible.

- At an advanced stage (breakage), it is necessary to stop sailing immediately and to have the mast compression post replaced, before going back to sea, by a Lagoon dealer or Service Center who have a dedicated and proven Lagoon methodology.

- The external base of the mast compression post may be corroded if it was exposed to water (ex: if the 2 front windows remain open during navigation) and not maintained when first corrosion signs appeared. If it is an early stage of corrosion, a simple maintenance treatment is sufficient to stop the phenomenon, otherwise, the mast compression post must be replaced.

1.6. For how long have you been aware of this issue?

- At the end of December 2022, for the first time, two cases of damaged upper area of the mast compression post were reported to us, which fortunately did not result in any consequences.

- At this stage, we have carried out in-depth analyses of these cases and a series of inspections on a significant number of Lagoon 450, which enabled us in mid-March to confirm that the mast compression post on most of the inspected boats are fine.

- However, because safety is a top priority for us and as a precautionary measure, we recommend you, if your yearly maintenance is planned beyond 6 months to get your mast compression post and your mast cable routing checked by your Dealers or Service Centers network.

1.7. Are all Lagoon 450 concerned?

- More than 1,000 Lagoon 450 are sailing safely, some of them for more than 10 years.

- Following the 2 cases that were reported to us in December 2022 and after the inspection of a significant number of Lagoon 450, we have found a very few cases.

- Nevertheless, as a precautionary principle, it is important to check each Lagoon 450 because the risk of accelerated ageing of the mast compression post depends on the history of use, maintenance, age of the boat as well as on interventions that have been carried out at the level of the passage of the mast cables in the mast compression post.

1.8. Are all Lagoon 450 concerned by this risk of corrosion?

- More than 1,000 Lagoon 450 are sailing safely, some of them for more than 10 years.

- Following the 2 cases that were reported to us in December 2022 and after the inspection of a significant number of Lagoon 450, we have found a few cases.

- Nevertheless, as a precautionary principle, it is important to check each Lagoon 450 because the risk of accelerated ageing of the mast compression post depends on the history of use, maintenance, age of the boat as well as on interventions that have been carried out at the level of the passage of the mast cables in the mast compression post.

1.9. Are there other Lagoon models affected by this risk of damage to the mast compression post?

- The Lagoon 450's mast compression post is unique in its design, both in its structure and in the materials used.

- Because safety is a priority for us, when informed of the isolated cases reported to us, our technical teams carried out additional investigations than on other older models and no case of mast compression post damage was found.

2. About the Lagoon 450 mast compression post checkup

2.1. What is this campaign about?

- We have decided to upgrade Lagoon 450 maintenance frame by adding from now on to its requirements the check of the mast compression post status and of its mast cable routing, after the detection of a few isolated cases of accelerated steel corrosion at the end of December 2022.

- It consists of a visual inspection of the mast compression post to check if it is intact, corroded, or even damaged and of its mast cable routing positioning.

- To do this, it is necessary to dismantle the ceiling and remove the PVC covering, an operation carried out by a dealer or a Service Center which requires less than 2 hours, following a methodology that we make available to them.

2.2. How to proceed to perform this check?

- Lagoon dealers or Service Centers will check the condition of the mast compression post, following the provided methodology.

2.3. When should I get my mast compression checked?

- Only a small number of Lagoon 450's could be affected by premature ageing of the mast compression post, which depends on the use, the history of the boat as well as the interventions that have been carried out at the level of the passage of the mast cables in the mast compression post.

- Therefore, because safety and quality of its boats is our utmost priority, we recommend you, if your yearly maintenance is planned beyond 6 months to get your mast compression post and your mast cable routing checked by your Dealers or Service Centers network.

2.4. Why do you recommend checking the mast compression post before its annual maintenance if it is planned beyond 6 months?

- Lagoon 450 annual maintenance will integrate the mast compression post status check from now on.

- Even if only a small number of Lagoon 450's could be affected by premature ageing, we recommend you, by precaution principle, because this is an important part in terms of safety, if your yearly maintenance is planned beyond 6 months to get your mast compression post and your mast cable routing checked by your Dealers or Service Centers network.

2.5. What are the signs that should alert us to the condition of the mast compression post?

- If the mast compression post shows signs of ageing (corrosion, cracks, breakage) we invite you to have it replaced by your Lagoon dealer or Service Center to whom we have sent an adapted replacement methodology.

- If the cable routing at the mast foot does not comply with the rules of the art, it also must be correctly repositioned.

2.6. If an owner does the check himself, in case of doubt, who can he contact?

- In case of signs of ageing (corrosion, cracks, breakage), we invite you to have your mast compression post checked by your Lagoon dealer or Service Center as soon as possible to confirm the stage of ageing of your mast compression post and proceed with its replacement, if needed.

3. About the Lagoon 450 mast compression post diagnostic

3.1. If the upper arear of the mast compression post does not have a crack, but rust is present on the outer part of the mast compression post. Should it be replaced?

- No, the mere presence of rust does not prevent safe sailing.

- We invite you, in case of doubts to have your mast compression post checked by your Lagoon dealer or Service Center.

3.2. What to do if the mast compression post is damaged?

- If the mast compression post is damaged, it must be replaced.

- At an early or intermediate stage, if upper area of the mast compression post shows the beginning of a crack or traces of corrosion, it is recommended to sail with the engine to limit the compression at the mast and to contact your dealer or your Lagoon Service Center. The dealer will inspect the mast compression post, make a diagnosis, contact the Lagoon boatyard to check the availability of replacement parts and will organize a replacement as soon as possible.

- At an advanced stage (breakage), it is necessary to stop sailing immediately and to have the mast compression post replaced, before going back to sea, by a Lagoon dealer or Service Center who have a dedicated and proven Lagoon methodology.

3.3. The upper area of my mast compression post has crack(s), can I still sail?

- If the upper part of your mast compression post shows the beginning of a crack or traces of corrosion, we recommend you sail under engine to limit the compression at the mast and to contact your Lagoon dealer or Service Center.

- He will inspect your mast compression post, make a diagnosis, contact the Lagoon boatyard to check the availability of replacement parts and will organize its replacement as soon as possible.

3.4. The upper area of my mast compression post has breach(es), can I still sail?

- If your mast compression post shows signs of breach, it is necessary to stop sailing immediately and to have the mast compression post replaced, before going back to sea, by a Lagoon dealer or Service Center who have a dedicated and proven Lagoon methodology.

3.5. Why checking my mast compression post every year if it is fine?

- Only very few cases have been identified but:

- This is an important part in terms of safety.

- The risk of accelerated ageing of the mast compression post depends on the history of use, maintenance, age of the boat as well as on interventions that have been carried out at the level of the passage of the mast’s cables inside the mast compression post.

- It is therefore important to check the condition of a mast compression post every year as a precautionary measure, even if it is in perfect condition today and, at the same time, to ensure that the mast cables are correctly routed through the mast foot.

3.6. Should I replace my mast compression post if it is fine?

- If a mast compression post is intact, there is no need to replace it, it will be annually checked, within the new upgraded maintenance frame of the Lagoon 450.

- At the same time, you should also check that the mast cables are correctly routed to the mast foot, as indicated in the inspection note.

3.7. Is the new mast compression post the same as the initial one? If not, what are the differences?

- Since the Lagoon 450 is no longer manufactured today and as we are constantly improving our technologies and products, the new mast compression post has benefited from several improvements, in particular to limit water ingress which causes corrosion.

3.8. If I replace my mast compression post, do I still need to check it every year?

- You will not need to check the mast compression post itself as the replacement mast compression post we offer is a new mast compression post with improvements, such as limiting water ingress that causes corrosion, as we are constantly improving our technologies.

- It is still important to check, every year, that the mast cables are correctly routed into the mast foot, which will be done within the upgraded Lagoon 450 annual maintenance frame.

3.9. Rather than check my mast compression post every year, why not directly change it?

- If a mast compression post is intact, there is no need to replace it, and no specific check to organize, as it will be annually checked, within the new upgraded maintenance frame of the Lagoon 450.

- Nevertheless, if you wish to do so, nothing prevents you from replacing his mast compression post, especially if the boat is old.

- In this case, you just has to contact your Lagoon dealer or Service Center to organize this replacement, without any emergency.

3.10. How long will my boat be immobilized if the mast compression post needs to be changed?

- We have developed a replacement methodology that involves a downtime of about 2 working days.

- The planning of the operation also depends on the delivery time (shipping and customs conditions) and also on the availability of your dealer or Lagoon Service Center.

3.11. How much the mast compression post replacement cost?

- Depending on the market, the cost will vary, but the replacement kit costs about 750€ HT, excluding shipping (public price), and takes about 2 days of labor.

3.12. Can I get my mast compression post replaced everywhere?

- This replacement can be done at a Lagoon dealer or Service Center which has a methodology for intervention developed by the Lagoon technical services.

3.13. Will you certify the replacement of the mast compression post?

- No, your invoice for the replacement work alone is sufficient proof, if needed.

3.14. Will my catamaran lose value if I don't do this operation?

- No, because if your mast compression post is intact, there is no need to replace it, especially since the phenomenon, according to our investigations, only concerns a limited number of boats, who have experienced specific conditions of use, or where the interventions carried out at the level of the passage of the mast cables in the mast compression post have not been carried out according to the rules.

- In 10 years of marketing the Lagoon 450, only 2 cases were reported to us in December 2020.

- Checking the mast compression post every year within the upgraded Lagoon 450 annual maintenance frame, will, on the contrary, maintain its resale value.

3.15. Will you cover the mast compression post replacement?

- No, the cost of material and labor will be charged to you, as this phenomenon depends on the use, the history of the boat, its maintenance as well as on the interventions that have been carried out at the level of the passage of the mast cables in the mast compression post.

GOIOT ESCAPE HATCH CONTROL AND REPLACEMENT

GOïOT SYSTEMS have launched a generalized recall campaign due to a risk relating to escape hatches delivered before September 2018 that could jeopardize the safety of navigation.

The search for reliability and safety for our customers in the construction of our boats has always been a priority objective for Lagoon.

For 12 years we have been equipping our catamarans with GOïOT fixed hatches. In April 2019, we have become aware of a few rare cases where the glazing has away from the aluminum frame, with the result that water has been able to enter the boat.

This is why Lagoon set up a procedure and has put a technical team at your disposal to organize making these panels safe, and to answer your questions. The dedicated team can be contacted at the following email address: Lagoon19009@cnb.fr.

HOW TO GET THE BEST OUT OF A LAGOON 450?

LAGOON 450 MAINTENANCE TIPS

10 GOLDEN RULES FOR OPTIMIZING MAINTENANCE

1. Detailed inspection of hull(s) underwater area including antifouling condition

A periodical haul out and bottom paint of your boat will keep her original performances and avoid any adhesion of marine vegetation.

The type of the water where you boat sails determines how to choose the antifouling paint as well as how often to carry out these haul-out and bottom paint. Do not hesitate to contact your nearest Lagoon dealer for advice.

2. Regularly inspect deck surface and hardware parts

3. Periodically, inspect standing rigging and tighten adjustments

4. Annually check on mast compression post

5. Regularly run rigging inspection

6. Periodically, inspect, clean and grease of hardware parts

7. Periodically, complete steering system inspection

8. Periodically, control electrical circuits and their maintenance, electronic circuits and their components as well as engine (s) and generator maintenance

9. Periodically, control interior equipment and wooden layout status

10. Always inspect the boat when you encounter difficult or exceptional sea conditions or following a sea event to prevent possible damage, which could progressively worsen over time.

11. Before any purchase or resale of boats and before transaction, it is highly recommended to carry out a preliminary survey performed per a certified surveyor approved by the local authorities of the country.

MAINTENANCE PLANNING

The information given hereafter is not an exhaustive list and may be adapted, depending on the use of your boat.

HULL / DECK FITTING / HULL

• Clean the hull with appropriate products QUARTERLY

• Clean s/s parts QUARTERLY

• Dismount, clean and grease winches ANNUAL

• Check the watertightness of the sea-cock fittings BI-ANNUAL

• Clean the sea cock fittings and strainers from the outside BI-ANNUAL

MOORING / WINDLASS

• Rinse ground tackle and anchor locker with fresh water WHEN USED

• Check the gypsy and anchor/chain fastening device BI-ANNUAL

• Check windlass brake system QUARTERLY

• Check mooring lines and fenders BI- ANNUAL

• Check the electric connections (remote control, relay, etc.) QUARTERLY

RUNNING / STANDING RIGGING / SAILS

• Have checked & adjusted standing rigging tension by a professional ANNUAL

• Have checked mast compression post by a professional ANNUAL

• Lubrificate the different travellers with teflon QUARTERLY

• Check and tighten the different shackles QUARTERLY

• Check the running rigging tightening QUARTERLY

• Check the halyard and sheet for wear points QUARTERLY

• Rinse the whole running rigging and sails QUARTERLY

• Check the mainsail battens and main seams QUARTERLY

UPHOLSTERY AND COVERS

• Rinse / clean the different covers QUARTERLY

• Dry the outside upholstery before its storage WHEN USED

REFRIGERATION UNIT

• Defrost the refrigerators and conservator QUARTERLY

• Check the door joints QUARTERLY

AIR CONDITIONING

• Check the sea cock and clean / change the different

◦ sea water filters QUARTERLY

• Dust off the unit heater fans ANNUAL

ELECTRICITY

• Check and tighten the battery terminal connections and main switch connections. BI-ANNUAL

• Check and tighten the main relay terminals

◦ (winches, windlass, etc.) BI-ANNUAL

ENGINES AND GENERATOR

• Check oil level QUARTERLY

• Check belt tension QUARTERLY

• Clean the sea water strainer QUARTERLY

• Check for leaks (oil, water, fuel) and smokes QUARTERLY

• Check and drain the decanter filters (fuel) QUARTERLY

REFER TO THE ENGINE MANUFACTURER’S GUIDE WATERMAKER

• Check and clean the sea water suction strainers QUARTERLY

• General inspection by the manufacturer ANNUAL

PLUMBING

• Check the automatic bilge pumps and alarms QUARTERLY

• Rinse the black water tanks QUARTERLY

• Check the manual bilge pumps QUARTERLY

• Check the pressure water pump QUARTERLY

• Check the different drains and scuppers QUARTERLY

• Open and close the different valves on board

◦ grease if necessary BI-ANNUAL

LAGOON 450 NAVIGATION TIPS

PREPARATION

The initial launching and the first tests of the different equipment shall be carried out by your dealer so that you can expect to enjoy the warranty in case of some equipment failure.

All further handling shall be carried out with the highest care by professionals. If the LAGOON boatyard is not involved in your handling operations, they cannot cover under guarantee any possible accidents linked to handling.

If later you have to launch your boat yourself, you should take the following precautions:

• Retract the sensors under the hull into their housings (they may be damaged by the handling slings).

• Check the water suction boxes for cleanliness.

• Turn off all the water inlet and drain valves (grey waters, black waters, engine).

• Check the anodes are in good condition and properly installed. An anode shall never be painted

In case of crane lifting, install a bow mooring rope, a stern mooring rope and fenders. When using a crane to move the boat, check that slings cannot touch any device (depth finder, speedometer, etc.) nor the propellers. The crane hook will be fitted with a gantry or a spreader system with two slings.

The slings shall not be connected directly onto the hook, as it would result in unusual compressive stresses on the hull.

• Crane lifting should be carried out slowly.

• Control the movement of the boat using mooring ropes.

Mast stepping and removal shall be carried out by a professional.

• When stepping the mast up, the professional rigger shall follow the mast maker tension prescriptions and shall aim to the minimum static tension (Dock Tune) recommended by the mast manufacturer.

SAILING ADVICES

Sailing, motoring and anchoring shall be processed in areas with sufficient water below the keels to avoid contact with the ground, taking in account the sea state and the other boats around.

BEWARE

A catamaran is about 6 times more resistant to heeling than a monohull. In naval architecture, it is referred to as up righting moment multiplication of the weight of the boat by the transversal distance between the center of gravity and the center of flotation (or bottom).

This fact has real consequences as for the sailing and sail trimming of a catamaran.

The fact that the boat does not heel may mask over canvassing, which may be very dangerous for the crew and the boat. Therefore, you must permanently keep a close eye on the speed of the true wind and trim the sail surface according to the latter as a matter of priority.

The below-mentioned trims apply in a calm sea. When the sea is brown, you shall reduce earlier by 10% as far as the speed of true wind is concerned.

And as a general rule, it is absolutely imperative to permanently try to ease up the boat rather than to stress her.

You will always try to have the forward edges of the sails facing the apparent wind, and to have the sail not sheeted home, so that the airflow behind the sail may be laminar, that is to say so that it may go off the aft part of the sail without any disruption.

In case you shouldn’t follow the recommendations below, it might be dangerous for the boat and the crew, and, in case of an accident, the manufacturer’s responsibility would not be involved.

TRIMMING WHEN CLOSE HAULED

This means that true wind is between 75 and 50° (wind force given in apparent wind). These figures are given for reference only and are to be adapted regarding external conditions.

• From 0 to 16 knots: full sail; sheet traveller 30 cm above the centre line of the boat, mainsail sheeted with a slightly open leech (boom on the centre line of the boat). The genoa is trimmed so that it skims the spreader, the genoa traveller is set so that the angle of the genoa sheet is the continuation of a straight line that goes through the sheet clew and the luff, at 40% of its height.

• From 16 to 20 knots: full sail; the sheet traveller goes up 60 cm above the centre line of the boat, mainsail sheeted with a leech a little more open (boom always in line: therefore, you must ease off the sheet). The genoa traveller remains at the same place, but the sheet is adjusted so that the leech is 10 cm far from the spreader.

• From 20 to 26 knots: 1 reef, full genoa; the sheet traveller goes back to 30 cm above the centre line of the boat. The genoa traveller remains at the same place, but the sheet is eased off so that the leech is 20 cm far from the spreader.

• From 26 to 30 knots: 1 reef, 75% of the genoa; the sheet traveller goes up 60 cm above the centre line of the boat. The genoa traveller remains at the same place or slightly goes forward but it is adjusted so that the leech makes a propeller shape where the upper part let some air go off in increases of wind.

• From 30 to 36 knots: 2 reefs, 60% of the genoa; the sheet traveller is back 30 cm above the centre line of the boat, the sheet is 50 cm eased off and the boom is leeward.

• From 36 to 45 knots: 2 reefs, genoa 40%. The sheet traveller is on the centre line of the boat, the sheet is 1 meter eased off and the boom is leeward. The genoa traveller goes slightly forward, the sheet is eased off in order to open wide in gusts.

• From 45 to 55 knots: 3 reefs only (or try sail, or lying to), the traveller is on the centre line of the boat, the sheet is 1 meter eased off and the boom is leeward. The boat would be more at ease scudding in such a weather.

• Over 55 knots: lying to, sea anchor, or preferably scudding.

TRIMMING WHEN DOWN WIND

This means that true wind is between 75 and 130° (wind force given in apparent wind). These figures are given for reference only and are to be adapted regarding external conditions.

• From 0 to 23 knots: full sail; the traveller can be set at different places ranging from 1 meter off the centre line of the boat to the end of the track, depending on the angle of the wind. The sheet is eased off so that the boom may be leeward and 50 cm far from the traveller in dead calm then up to 2 meters when the wind strengthens. In all the cases, you will avoid having more than one batten chafing against the upper shroud, in the fairest points of sailing. The genoa is eased off in order to have its average front edge facing the apparent wind.

• From 23 to 28 knots: 1 reef, full genoa. The trimmings are similar.

• From 28 to 33 knots: 2 reefs, 80% of the genoa. The trimmings remain similar.

• From 33 to 38 knots: 2 reefs, 60% of the genoa. The trimmings remain similar.

• From 38 to 45 knots: 3 reefs (or mainsail lowered and slightly more genoa), genoa 40%. The trimmings remain similar.

• From 45 to 55 knots: mainsail lowered, genoa 40 to 30% quite hardened in order to avoid flapping.

• Over 55 knots: scudding, depending on the sea, you will set mooring ropes from one transom extension to the other one in order to reduce the speed of the boat.